Using the OneVision Seam Stripper with a aerosol dome removal tool thecan can be sectioned then the cover hook can be removed to check for wrinkle

SeamMate will check the parameters of the double seam on aerosol cans.

For aerosol can makers here is a realistic measurement system to replace the optical comparator. MultiVision™ gives the can maker the accuracy and repeatability required and saves time. The machine is robust so that it can happily operate on the factory floor next to the line. Additional process dimensions can be checked during stages of the process such as flanges and shapes. MultiVision can also be used to scan aerosols made from Aluminium and Plastic. Scanning of body profiles are also available on request. Typically 6 cans can be processed in 10 minutes. The database stores all the records and a SPC system can monitor your process. Hard copies of reports are available at a push of a button. No manual transfer of data to records. MultiVision can be networked with report stations in remote locations and with SeamView a visual display can show trends with alarms for process deviation.

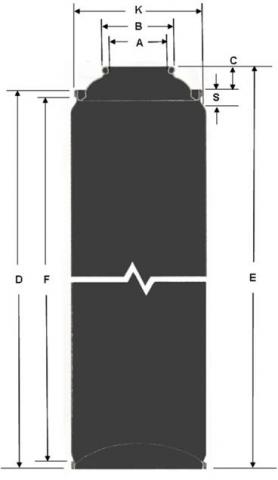

For aerosol cans MultiVision measurers the following parameters as standard:

• Overall Can Height

• Height over Double Seam

• S dimension

• K dimension

• Diameter over Double Seam

• Height over Double Seam